All You Need to Know About Fluid Conveyance

Fluid conveyance is the transfer of fluids, or gasses, from one point to another using various systems. This process is fundamental to countless industries and is an important part of any hydraulic system. Systems for fluid conveyance often involve pipes, hoses, valves, pumps, and other components designed to control flow rates, pressure, and direction. Selecting the correct type and size of conductor is critical for the proper operation of a hydraulic system. In this article, we will discuss the pros and cons of each type of fluid conductor and then talk about how to select the correct size for your application.

Types of Fluid Conductors

Steel Tube

Steel tubing is a good option for long runs. For example, if you needed to connect two components and they were at opposite ends of the chassis. Although, steel tubing Steel tubing is sized based on the outside diameter and wall thickness. When sizing steel tubing, it is important to know the inside diameter so that you are not affecting the fluid velocity in your system.

Black Pipe

We do not recommend the use of black pipe on hydraulic applications. It’s an old method of fluid conveyance that is out of date. Black pipe is rigid and hard to plumb. It’s susceptible to leaks, corrodes in outdoor and mobile applications, and can’t withstand the high pressure necessary on many hydraulic systems. In the world of mobile hydraulics, black pipe is too hard to plumb in the tight spaces of a truck chassis. You may find black pipe sections or fittings on the suction side of a hydraulic circuit, where there isn’t any pressure. You should never use black pipe on the pressure side of a hydraulic circuit.

Rubber Hose

These specialized rubber hoses are the most common type of fluid conductor. Rubber hose is designed to withstand the pressure and temperature required for mobile applications. It is also designed to handle being out in a harsh environment. It is the easiest to route and will flex with moving parts of the equipment to a certain extent. Hose is either designed to be used with the pressure side of your hydraulic system or the suction side of the hydraulic system. They also have a bend radious specification that rensures it doesn't get overbent or kinked.

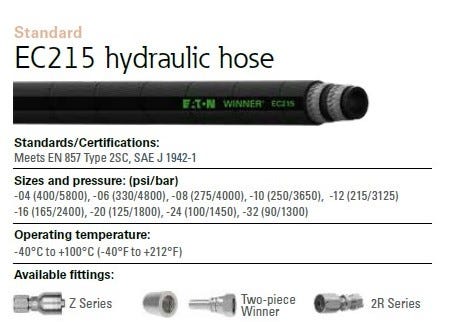

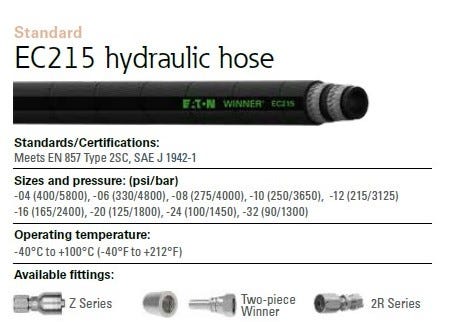

This chart is typically what you would find when you are trying to match the correct hose for the application. You will find the temperature and pressure ratings based on the size of the hose. It also tells you what type of ends are compatible with the selected hose.

Rubber Hose Size

It also comes in a variety of sizes. Hose is sized based on the inside diameter measurement. It is marked using the dash size system. The dash size refers to how many sixteenths of an each the hose is. For example, a -08 size hose is a ½” in diameter because 8/16ths equals a half inch. The size should be carefully chosen to match the amount of fluid flow and pressure that is required for the application.

Rubber Hose Ends

Specialized hose ends are crimped onto each end of the hose. Hose and ends must be compatible and crimped using the proper machine and specifications. Proper crimping of a hose end ensures that it can withstand the pressure rating of the hose. You must also make sure that the machine you own to crimp the hose ends is compatible with the style of hose ends and hose you are trying to crimp.

Rubber Hose Ends

It is extremely important that hose designed for the suction side of your hydraulic system is never used on the pressure side of the system. Suction hose is not constructed to withstand the pressures created on the pressure side of the system. On the other hand, pressure hose should also never be used on the suction side of the system. Suction hose is designed to not collapse. Pressure hose used on the suction side of the system can collapse creating a scenario where you can cavitate and destroy the hydraulic pump.

FORCE America offers a wide variety of hose and hose ends. We have the capability to make most any hose for your application. Call 1-888-993-6723 to speak to one of our knowledgeable salespeople.